Ford Focus Traction Control - How does it work?

I saw something in a datalog this week that made me think folk might be interested to see it.

A client was doing a data logging run for us in his FWD MK3.5 Ford Focus ST and in one of the logs he was struggling for traction which made for quite an interesting set of data that i thought may make a reasonable blog since i haven’t done one since early this year!

Traction control is baked into all modern cars and works exceptionally well.

Since the mid 2000s, traction control really has been exceptionally fast and efficient. Certainly it existed in the 90s but was a bit clunky and intrusive, but as modern PCM (Powertrain Control Module) technology and processing speeds advanced it became almost transparent in its operation. In most situations, the PCM monitors all four wheel speeds independently and knows precisely what their output waveforms should look like at all times, including the inherent differences they will give during cornering. (Your outside wheels roll faster than the inside wheels during cornering)

When the ECU sees one of the wheels unexpectedly accelerating faster than the others it knows that that wheel has lost traction and needs to be brought back into line with the others, this activates the PCM's Traction control strategy.

Slowing down a wheel can be done in multiple ways, up to and including applying the brake on just that wheel if need be.

But in the early moments of traction loss a small power reduction can be more effective. Now an engine power drop sounds as though it would feel quite dramatic doesn’t it? But in reality a modern PCM (By modern I mean anything in the last 15 years) can take control of an errant wheel in under one second!. It is so effective at doing this that most drivers will never even know they had a traction problem at all.

This is one of the reasons that modern vehicles seem to put so much power down without any problem at all. I mean, who remembers tuned Renault 5 and Ford Escort Rs Turbos back in the day? With anything approaching 200bhp they were just wheel-spin monsters right up and into 4th gear. (Yeah - I admit, that’s kind of what we loved about them back then)

Nowadays we can and do put double that kind of power through the front wheels with seemingly no problem at all don’t we?

Well actually, no, we usually don’t!

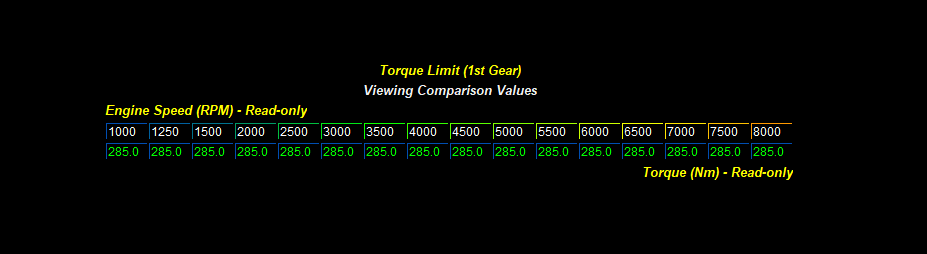

What actually happens is the PCM has tables built into it to limit the power output in the lower gears so that your 390NM and 250PS engine outputs far less in the lower gears that are likely to be traction limited.

This table from a 2017 Ford Focus ST250 is a great example:

That focus has a 390NM and 250PS output limit as standard, but in 1st gear it is further limited to 285 NM across the board. I bet you didn’t know that?

All modern cars are configured this way because, as I like to tell my customers from time to time: "Power is nothing without control..." and there is no point having power we cant use. A fast car is one that puts its power to the ground, not one that wheel-spins it all away.

Traction is actually optimised in many ways within the PCM, power output is usually reduced with large steering angles for example, and sometimes other engine limits will also improve traction too, such as the LSPI tables that keep the engine safe from engine damaging pre-ignition. These tables limit load at low engine rpm which of course, can improve traction.

There are other gearbox torque tables too, designed to keep the flow of power smooth so as to limit transmission damage and also serve as final output torque limiters. Naturally, many tuners just do away with the low gear torque and LSPI limits making it seem like a wonder tune. But its not, they just unlocked power that the powertrain experts in billion dollar test centres incorporated for very good reasons, in the case of the LSPI tables its normally to keep the rods in the block! Unlock a Focus Ecoboost LSPI table low down and cracked pistons will result at best - and a rod out the front door at worst. For this reason you will often hear me groan when I read an excited forum member declare he changed tuners and "It wheels spins as soon as you squeeze the throttle now..." Still, i guess it keeps engine builders in work.

Anyway, we need to get back into the actual subject, which is traction control and how it works...

So, my point is that modern vehicles usually have engines that are capable of breaking traction at any time should their full power be realised and they have been programmed by the manufacturer to put that power down in a controlled manner. Often, the only way to fully realise the engine's capability is to disable all traction control and stability control programs, (Sport buttons often relax these systems a little) at which point you often find you are left with a pretty undrivable vehicle the minute you roll onto a greasy road and try to accelerate the way you normally would! You would be surprised how often your traction control has saved the day and you just didnt know it was active.

So how does traction control tame all this power?

As always, we need to look at some data to illustrate this...

First, you really need to understand what a log with good traction should look like.

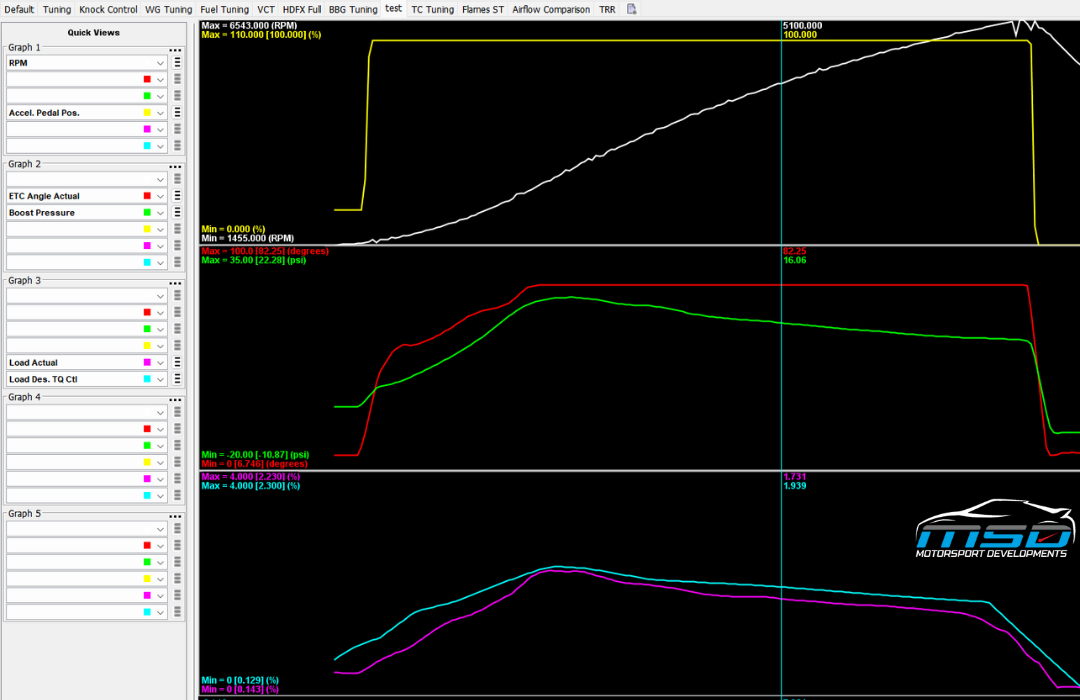

I have narrowed the data in my examples down to only the 6 most relevant parameters of the 30 that we would normally be logging during a typical E-tuning session on a Ford Focus ST 250. Each trace is colour coded as follows:

(And its name and colour can be seen on the left hand side of the screenshot too.)

- White = Engine speed

- Yellow = Accelerator pedal position

- Red = Electronic throttle angle

- Green = Boost pressure

- Cyan= Load Requested

- Purple = Load actual

So, here is a log of a MK3 Focus ST with no traction problems doing a 3rd gear pull from 2000 - 6500rpm

You can see in the log above that the driver has his foot to the floor, (Yellow) the RPM is climbing nicely (white) The PCM has the electronic throttle open all the way (red) and the boost has peaked and is slowly falling (Green) and this is all happening to a load target (Cyan) that is being closely followed by the PCM (Purple). Incidentally: You should understand that load is all the PCM cares about and load = power output. Everything a modern PCM commands of the engine will be in load, and the boost is delivered for no other reason than to achieve that load, NOT the other way round.

As a calibrator, (having studied the other 24 parameters too of course) I can see that this vehicle just needs the boost increased as part of the E-tuning process but it is otherwise fine. (Its probably good for a little ignition too on his 2nd E-tune.)

It was however one of this same clients other logs that I thought people may find interesting because he had bad traction and the log very nicely illustrates how the PCM can take back control of a wheel with no traction very, very fast! But the log was an especially good example because in this case, the car kept losing traction again and again! I suspect the driver of this vehicle may well have been unaware of this even happening as each intervention took less than 0.75 seconds and as you will see, he kept his foot pinned.

I have split the data down into smaller sections so we can look at the parameters in more detail.

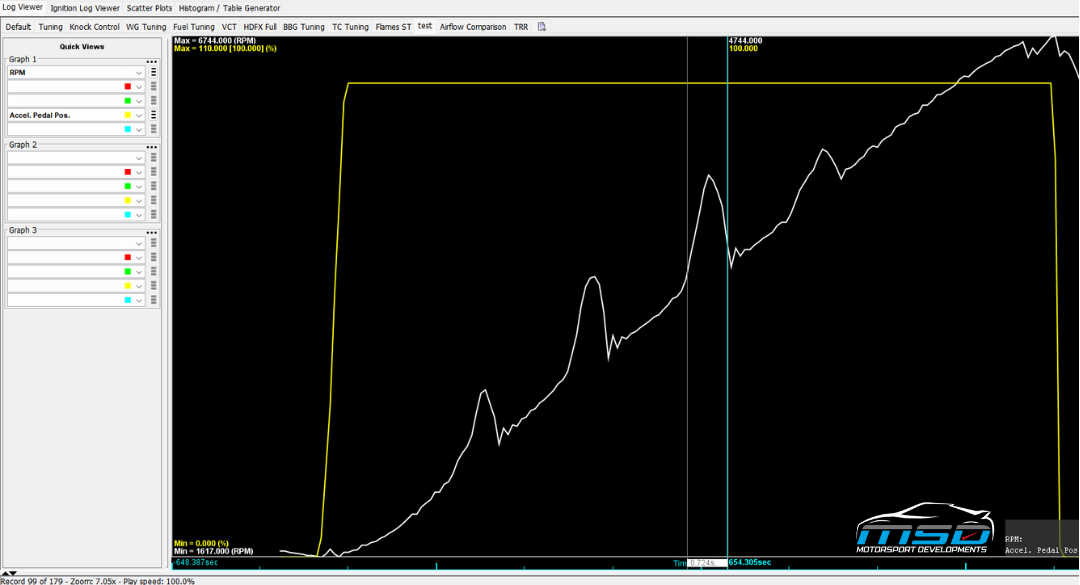

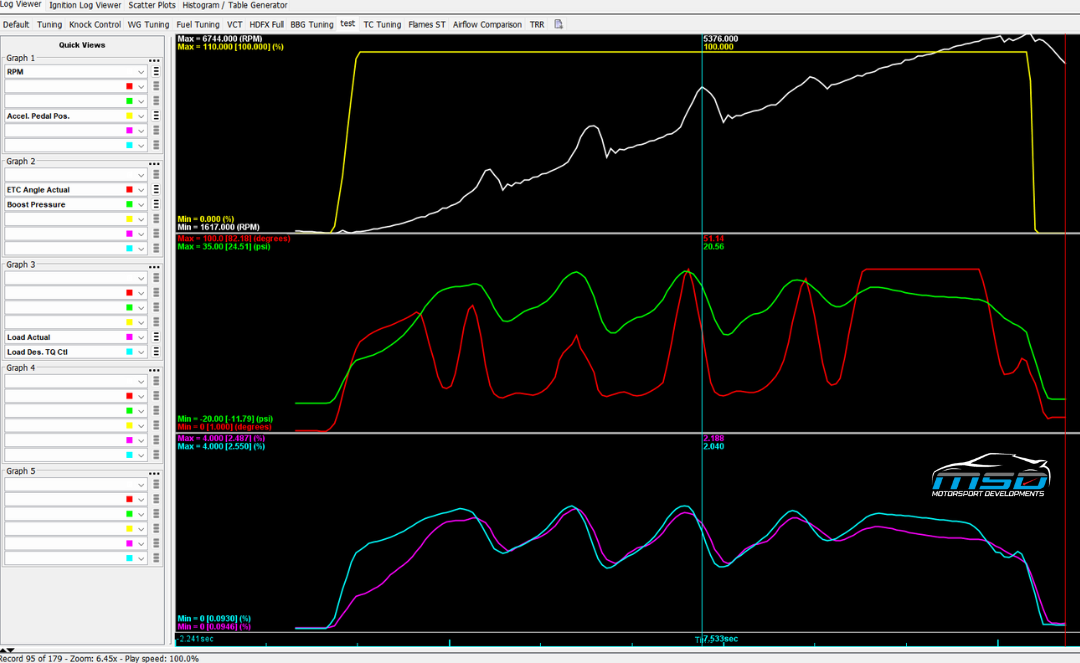

In this next image you can see the following data:

- White = Engine speed

- Yellow = Accelerator pedal position

You can see on this run that the engine speed rises very quickly and drops back again in 4 places. This indicates either loss of traction at one or more wheels or of course, clutch slip. (The PCM will confirm this is traction loss using wheel-speed data from the Canbus.) The accelerator pedal position trace (Yellow) shows us that the driver did not lift at all from full throttle during these events.

It gets more complex from here on in, so pay attention at the back...

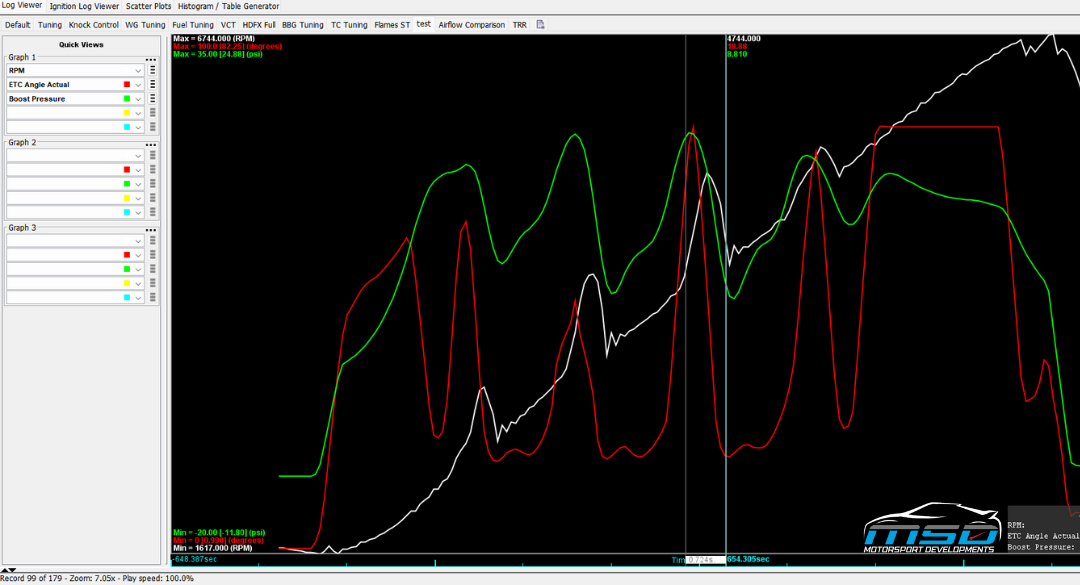

In this next image you can see why these traction loss events are so short. You will see that the PCM is using the electronic throttle (Which is totally independent of the drivers foot) to control the boost pressure in the manifold, completely ignoring the drivers wish of keeping the throttle open, this is because the PCM regards traction as a higher priority.

- White = Engine speed

- Green = Boost pressure

- Red = Electronic throttle angle.

We can see from this data how the ecu has dropped the boost (Green) just enough to take control of the traction (white) and then reintroduced it, all independent of the drivers throttle command. I have highlighted the sectional area across the largest of the traction loss spikes in the image and the time frame at the bottom shows that the PCM had that wheel back under control in a mere 0.724 seconds.

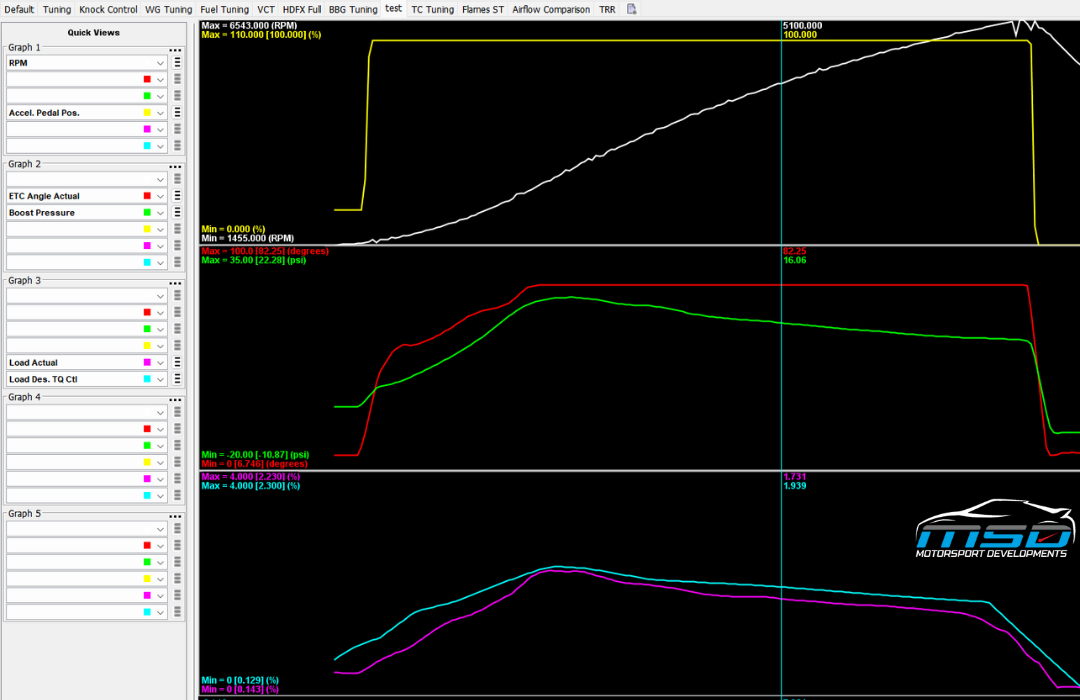

Now you understand each trace seperately, you can look at the system working as a whole in the following screenshot where i have included all 6 parameters from original, good traction log.

- Yellow = Accelerator pedal position

- White = Engine speed

- Green = Boost pressure

- Red = Electronic throttle angle

- Cyan= Load Requested

- Purple = Load actual

You can now see the various parameters in action together. The driver has his foot to the floor (yellow). The wheels are losing traction multiple times (white) and each time they lose traction, the PCM commands a lower load (Cyan) and achieves this by closing the throttle (red) and limiting boost (Green) until that load is achieved and traction is restored, at which time it feeds the engine load back in. Unfortunately in this case the wheels loose traction again and it has to repeat this multiple times until around 5000 RPM where permanent traction is restored and the full load request is maintained with a wide open throttle.

I will remind you again how a normal run looks, just for easy comparison.

As you can see, without traction loss, the ECU just tries to maintain its load target, the throttle stays wide open and there are no interventions at all. A relatively simple system, but working at very high speed with a very fine degree of accuracy.

So the next logical question is this:

At what point does the PCM decide to take control, and how did the PCM know how much load to remove in order to regain traction?

Well, the PCM's traction control strategies run on a wheelslip allowance basis. So in normal drive mode with all systems active it may allow for example, 5% wheel slip. So once the wheel speed differential allowance has been breached the system would take action. These allowances are often different across situations (Such as moving off from a standstill) and drive modes such as sport mode which commonly increases the allowance for more enthusiastic driving.

Its an incredibly accurate system and its programmable and switchable configuration has given rise to some interesting cars. The MK3 Ford Focus RS drift and race modes are a great example of this traction control flexibility, allowing the back of the car to swing round on a race track, yet the PCM is still retaining factory control should the driver push too hard!

As for how does it know how much to back off the load, the PCM strategy is completely torque based and the engineers have modelled the torque down to a single newton meter. The PCM knows precisely how much load is required to make X torque so the required torque reduction to take control of an errant tyre simply becomes a maths function with the answer coming in load units. For example, in the case above the PCM commanded a smooth load reduction of 0.85.

Torque control at the tyre actualy comes by way of many complex systems in the PCM, the most powerful but least accurate probably being individual wheel brake activation, followed by the throttle based load control system I have illustrated today. But there are others too, including the system that Ford call the Torque Reduction Ratio system. This system authorises the PCM to use fuel enleanment and spark retard to reduce power outputs from as little as 0.5% (Torque targeting adjustments usually) up to a full on power cut (overrun fuel shut-off and rev limiters for example) And these systems often come into play during a traction control event too, but are a little outside the scope of this already too long blog...

Further Reading...

And that’s all for what was supposed to be a "quick blog", If you are interested to read a little more about the inner strategies within the Ford Ecoboost PCM, such as how it can infer a fuel octane, or how these systems are modelled in actual Nm of torque and convert your torque request into air loads, then you will likely find some of my other Ecoboost blogs of interest.

Click the link below to go right there...

Author:

Stewart Sanderson - October 20th 2023